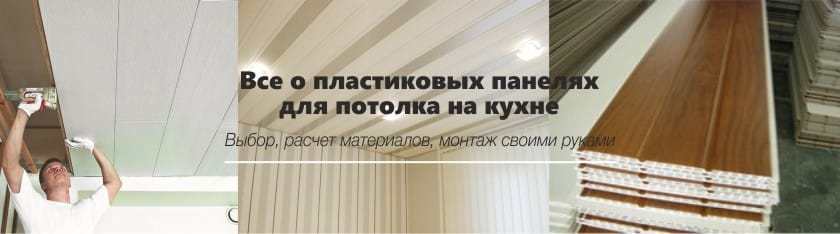

Finishing with plastic panels allows you to get an aesthetic ceiling covering, which will be not only beautiful, but also easy to maintain - while the costs for its installation are minimal. What is the benefit of plastic panels on the ceiling of the kitchen? Consider their main advantages in the "kitchen" conditions.

The advantages of PVC panels in the kitchen

First, this finish is incredibly easy to clean. For its cleaning does not require special substances - pollution and soot deposited on the kitchen ceiling, are easily removed. Restrictions on the choice of cleaning products exist only for glossy and mirror surfaces - here you can not use abrasives.

Secondly, PVC panels will survive even the strongest flooding - and will dry out on their own without damage, without requiring any intervention from you. It will be necessary to remove the ceiling from plastic only if the amount of water that has entered your apartment is very large. It is because of the moisture resistance of the material it is most often used for cladding the ceiling in the bathroom and on the balcony. Well, and in the conditions of kitchen, finishing by plastic panels is especially actual if you are often flooded from above.

Third, the ceiling panels in the kitchen help to hide communications (wires and pipes).

Fourthly, a significant plus of this type of suspended ceilings is that they do not require a perfectly flat ceiling and hide even its significant defects.

It is worth noting the advantages of PVC ceilings such as:

- Stability and stability of the form even with sharp temperature changes;

- The possibility of trouble-free installation attractive spotlights anywhere coverage;

- Repair and installation of plastic ceilings can be done independently. For this, a frame is assembled, and plastic panels are attached to it from above. To create a perfectly flat surface of the base for this is not necessary;

- This finish allows you to perform additional sound insulation due to the inclusion in the frame of appropriate materials;

- Plastic ceilings are environmentally safe and have no foreign smell, which compares favorably with the tension structures;

- Affordable price.

Among the drawbacks of PVC ceilings, it can only be noted that the construction refers to mounted ones, which means it will slightly reduce the overall height of the ceiling.

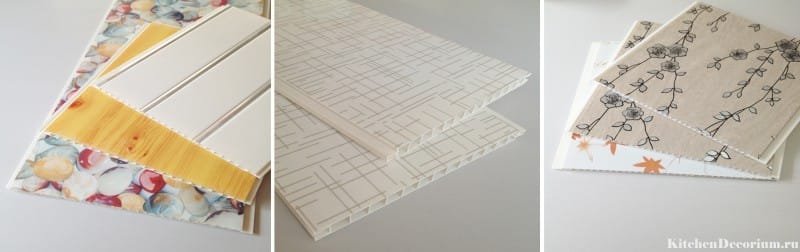

Choosing a design

Finishing by plastic panels is also a set of various design decisions. Such a ceiling can be a mirror or translucent, imitating ceramics, bamboo, metal or marble, "under the tree" or even "under the skin."

Of course, when choosing textures and colors, the overall stylistic decision of the room is crucial, but it is not recommended to make a dark plastic ceiling.Traditionally used pastel colors, shades of blue and beige. By the way, light colors will also visually expand the space.

White plastic will be very similar to the more noble white wooden wall paneling and will fit into the interior of any style and color.

Matte panels will look better in the kitchen, and gloss is more appropriate in the bathroom.

What to look for in the store

When you have decided on the design, you need to go to the issue of purchasing material. It is important that you purchase high-quality plastic panels, and for this you need to consider the following recommendations:

- Plastic sheets and their edges must be even - even the slightest roughness in the joint zone will lead to the fact that the integrity of the suspension structure is broken;

- Each of the PVC panels should be evenly painted, without inclusions. If the design involves color transitions within the same web, then it should be uniform and smooth;

- Panels should also not be too thin and soft.

- To check the quality of plastic, squeeze the panel with two fingers and bend its corner several times - the quality panel should not crack and, moreover, break, only a slight deformation is permissible.

PVC ceiling panels are lighter and more fragile than wall panels, and therefore transportation and installation must be done with great care.

We calculate the consumption of materials: panels, baseboards, profiles and fasteners

Thickness of PVC panels is often 5–10 mm, width is 250-500 mm, and length varies from 2.7 m (standard) to 3 m. Ceiling baseboards have a three-meter length.

To calculate plastic panels, first determine the area of the ceiling, and then divide this number by the area of one panel (indicated on the package). Add to the resulting figure 15% of the margin on the edges and round it up.

Along the perimeter of the kitchen, it is necessary to install UD (hard) guide profiles, and the supporting transverse bars of the frame should be light, i.e. CD.

Count the number of profiles for crates. To do this, draw on the sheet in a cage diagram of your ceiling in scale. Now mark the profiles that will be installed across the room parallel to each other. The distance between them should be about 60 cm. Calculate how many profiles will be needed, taking into account those that will be installed around the perimeter of the kitchen. Also count the required number of dowels (for fastening profiles) and self-tapping screws (for fastening panels) at the rate of: 1 dowel per 50 cm of profile and 1 self-tapping screw per 50 cm of PVC panel length. The crate can be made of wooden bars, then instead of screws, 6 mm staples are suitable. But keep in mind that the wooden frame will not last as long as metal.

To calculate the required number and length of baseboards, divide the ceiling perimeter by 3 (since the length of the plinth is 3 meters), and then round this figure up to a number that is a multiple of three.

What is required for the work - the necessary tools and components

We will need the PVC panel of standard dimensions (5-8 mm thickness, 6 meters length, 25 cm width) and the selected design. Also required:

- Profiles to create a frame;

- PVC baguette;

- Type L profile;

- Mounting angle;

- Wooden slats with a cross section of about 40x20 or 50x25 mm or metal profiles for fasteners of GK-systems;

- P-type metal hardware that is used in plasterboard ceilings.

As for the tool and fasteners, the repair requires the following:

- Screws, plastic dowels;

- Metal strong brackets and stapler;

- Screwdriver / drill;

- Pliers;

- Hammer;

- Scissors for metal or a hacksaw for wood (depending on what material is used to create the frame);

- Level;

- Roulette;

- Knife;

- Square;

- Pencil / marker.

Do not forget that the finishing of plastic panels is made in the kitchen, that is, in a place with high humidity.So that you do not have to do repairs here often, additionally process the wooden crate with a protective solution that increases the resistance of wood to moisture. If this is not done, then PVC will “lead” very soon.

Preparatory work

Before you hang plastic panels on the kitchen ceiling, it is necessary to prepare the base. Before attaching the frame putty and plaster off the main ceiling (not completely, but only flaking fragments).

Then proceed to create the frame under the plastic panel. For this you need:

- Mark the location of the bottom of the frame - it uses a tubular water level.

- In case you use a metal frame, then firstly UD-profiles are screwed to the wall. Between the bottom mark of the frame and the ceiling (base) must be at least 25 mm.

- After installing the UD-profiles, the main ones are mounted - from metal or wood. They are attached directly to the ceiling using U-shaped metal mounts. There is always a distance of less than 70 cm between fastenings. The smaller the pitch is, the safer and more rigid the whole structure will be. Screws are used for fixing wooden beams, and metal profiles are attached using “fleas”.

Plastic mount

To begin with, PVC sheets are cut - so that their length is less than the distance between the walls (in length) by 5 mm.

Work needs to start from the window. It is necessary to fasten the fastening strips to the installed profiles, the last fastening strip is mounted on the wall opposite to the window and at the very last.

Then, insert the baseboards into the grooves of the installed fastening strips, which were previously cut to the desired length.

The first panel is moved into the recess between the baseboard and the mounting plate, leveled and secured with screws with a wide cap. Next, each next panel is attached to the groove of the previous panel and is also screwed with screws to the frame.

Heating pipes can pass through the ceiling. To circumvent them, holes of the required diameter are cut out in plastic panels. And do not forget that near the pipes PVC trim can warp.

Before fastening, the last piece of PVC is necessarily cut along the side of the mounting edge to the desired width and inserted into the recess between the bar and the profile, and then into the groove of the penultimate panel.

Now it remains only to install the latest plinth and ceiling repair in the kitchen using plastic panels can be considered complete.

For more information about the installation of a suspended ceiling made of plastic PVC panels and wiring for the lamp, see the following video:

- Ceiling in the kitchen - 7 ways to design

- Rack ceiling in the kitchen - features of choice and installation

- Plasterboard ceilings in the kitchen - from design to installation

- Stretch ceilings in the kitchen - design, care, myths and reality

- Plastic panels in the decoration of the kitchen apron and walls

(Rate the material! Already voted:16 average rating: 4,31 from 5)

(Rate the material! Already voted:16 average rating: 4,31 from 5)

The ceiling of plastic panels certainly looks good! But getting dirty is good too) Although, despite what the kitchen is)